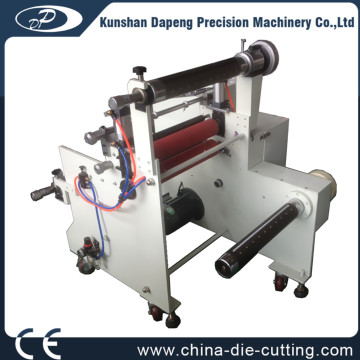

Film and Paper Lamination Machine

Basic Info

Model No.: DP-420TH

Product Description

Model NO.: DP-420TH

Classification: Cold Laminating Machine

Automatic Grade: Automatic

Plastic Film Mulching Modes: Cold Laminating

Performance: Dust

Laminate Layer: 2/3 or More

Transport Package: Wooden Case

Origin: Kunshan

Driven Type: Electric

Application: Film Material, Color Printing, Soft Board

Membrane Material: Light Membrane

Paper Size: A1--A6

Max Laminating Width: 650mm/420mm

Trademark: DP

Specification: SGS

HS Code: 8443911900

film and paper lamination machine

film and paper lamination machine Summarize

The machine is used for materials laminating, it can automatically count, setting length, stop, the whole machine frequency stepless speed regulation, magnetic particle clutch, Brake constant torque tension control, Traction, Rewinding pneumatic locking, Rapid loading and unloading etc. High precision, easy operation, it is Electronic insulation manufacturing plant supporting one of the necessary equipment.

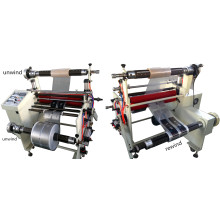

Main data and technical specifications

2.1 Max feeding roll length: 420MM/650MM

2.2 Max rewinding / winding diameter 450MM

2.3 Laminating speed 80M/Min

2.4 Laminating precise ± 0.2MM

2.5 Main Motor 0.75KW

Operation board explanation

Power: Plugging in the outlet, Start the power

Stop: Used for machine stop working mode.

Speed governing: Control the motor speed, knob to the right rotation, the motor speed will be higher.

Start: Used for machine start working.

Crawl: For machine start feeding material, feeding stop when hand off.

6. Meter-counting: The controller adopted Perimeter calculation method to calculate the length, the hall switch producing each pulse signal, the controller add one step value. The step value is different as the machine installation different, to increase the precise, require the step value the shorter the better, as shown in note 3, the four sensor points installed on the roller end, So that the drum circumference equal portions to shorten the stop length.

film and paper lamination machine technical data :

| max feeding width (mm) | main engineer power (kw) | speed (m/min) | size (mm) |

| 650/420mm | 3 | 60 | 1400*1200*1300mm |

| Feeding diameter (mm) | Rewinding diameter (mm) | presicion (mm) | power (v) |

| 500 | 450 | ±0.1 | 1 phase 220V 60HZ |

Contact us if you need more details on Paper Laminating Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Laminating Machine、Roll Laminator. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Laminating Machine > Cold Laminating Machine

Premium Related Products

Other Products

Hot Products

Pneumatic Hot Press Machine with Press Time ControllableConductivity Graphite Sheet Hydraulic Press MachinePet Hook Hang Tab Die Cutting Machine (DP-320B)CE Approved EVA Sheet Kiss Cut Die Cutting MachineAutomatic Screen Protector Film Slitting Laminating Machine (DP-1600)Dp-520 EVA Pad Die Cutting MachineRoll Film Die Cutting Machine (DP-420BII)Paper/Silicon/ Foam Tape Slitting Machine (DP-1600)Multifunction Slitting Rewinding Machine for Adhesive TapesRoll to Roll Label Punching Die Cutting Machine (DP-320B)Aluminum Foil Die CutterBrown Paper/Kraft Paper /Mylar Paper Cutting Machine (DP-600)Hydraulic Press Automatic Aluminum Foil Label Die Cutting Machine (DP-650)High Precision Jumping Sheet Die Cutting MachineAutomatic Hydralic Die Cutting MachineGasket and Packaging Protector Foam Die Cutting Machine